Our Products

We provide high-quality PVC, UPVC, SWV, PPRC, HDPE, and MDPE pipes, along with a wide range of fittings and accessories. Our products are designed for durability and reliability, suitable for residential, commercial, and industrial applications.

How can we help you?

SWV PIPES & FITTINGS

Standard Product Range

BS 3505, PS 3051, ASTM 1785

1″ to 18″ (in inches for PIPES)

32mm to 160mm (in millimeters for PIPES)

2″ to 8″ (FITTINGS)

8″ to 18″ (FABRICATION FITTINGS)

SWV Pipes and Fittings is a complete system of soil, waste and vent

pipe system made of un- plasticized poly vinyl chloride (UPVC) compound.

APPLICATIONS

• Water drainage and sewerage for buildings

• Disposal of industrial sewerage

• Agriculture irrigation

• Drainage for civil and roads

UPVC PRESSURE PIPES & FITTINGS

Standard Product Range

BS 3505, PS 3051

0.5″ to 24″ (PIPES)

0.5″ to 12″ (FITTINGS)

12″ to 24″ (FABRICATION FITTINGS)

UPVC Pressure pipes are highly recommended world-wide for water

supply, irrigation, sewerage, chemical and cold portable drinking

water. Having special feature of high pressure and low installation

cost.

APPLICATIONS

• Water supply system for portable water

• Industrial water supply

• Cold water line for air-conditioning, swimming pool etc

• Agriculture water supply

• Drip/micro irrigation

• Heavy industries, government projects & other projects

PPRC PIPES & FITTINGS

Standard Product Range

PIPES DIN 8077 – 8078. FITTINGS DIN 16962

20mm to 160mm (PIPES)

20mm to 160mm (FITTINGS)

PPRC Pipes & Fittings are made of best quality of polypropylene

random co-polymer. They are special recommended for hot and cold

water supply. Especially for commercial, residential and industrial

water treatment.

APPLICATIONS

• Hot & Cold water supply.

• Various industries

• Compressed Air

• Hospital, Hotels and apartments

• Chemical lines

HDPE PIPES & FITTINGS

Standard Product Range

PS 3580, ISO 4427, DIN 8074/8075

20mm to 800mm (PIPES)

63mm to 800mm (BUTT FUSION FITTINGS)

20mm to 110mm (COMPRESSION FITTINGS)

20mm to 315mm (SADDLE CLAMPS)

HDPE PE-100 pipes and fittings are made of best quality PE(Polyethylene) compound. HDPE pipes and fittings are highly resistant to environment stress cracking. HDPE pipes are best preferred for portable

water supply, irrigation, chemical and edibles. They can also be used

for ducting and disposal system. APPLICATIONS

• Water supply system

• External and internal drainage

• Disposal of chemical effluent and waste

• Submarine delivery system

• Sprinklers irrigation

• Telecommunication cable ducting

• In petrochemical, paper, paint, cement and industries

MDPE PIPES & FITTINGS

Standard Product Range

ASTM D 2513, DIN 8075, ISO 4437

0.5″ to 6″ (in inches) (PIPES & FITTINGS)

20mm to 315mm (in millimeters)

MDPE PE-80 Pipes & Fittings are made of best quality PE(polyethylene)

compound, which is synthetic pipe grade material made from distillation and cracking of crude oil. MDPE pipes and fittings are highly resistant to environment stress cracking.

APPLICATIONS

• Bio-gas, coal gas & natural gas

• For disposal of chemical effluent and waste

• Acid and Slurries transportation

• External and internal drainage

• In petrochemical, paper, dyes, paint, cement and industries

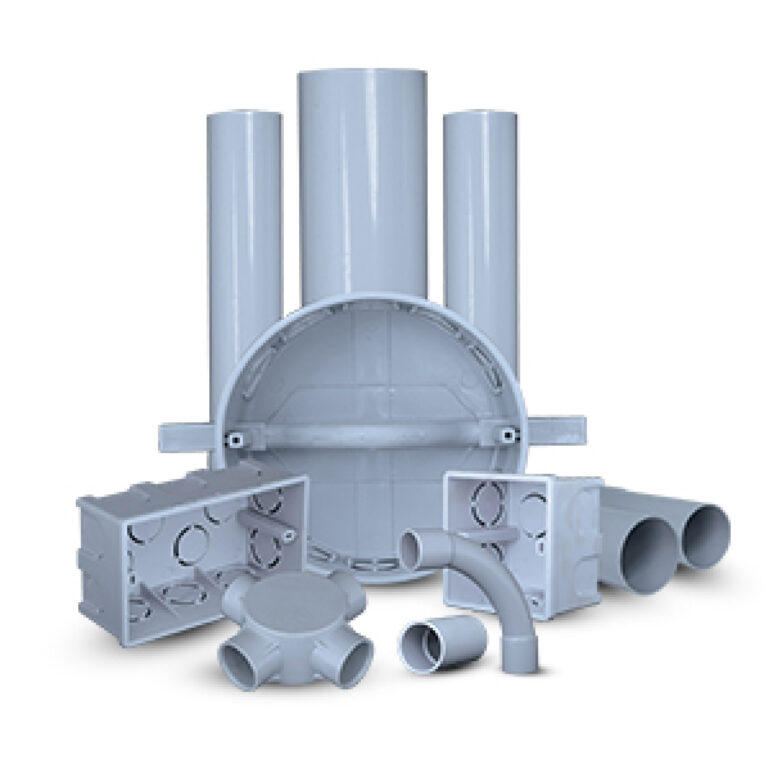

U-PVC ELECTRIC

CONDUITS

Standard Product Range

PS 1905, BS 6099

0.5″ to 6″ (in inches PIPES & FITTINGS)

U-PVC ELECTRIC CONDUIT products are suitable for power, telephone

and other electrical systems. These products can be used above the

ground or underground for installations. Light weight, cost effective,

long-lasting and come with UV protection.

APPLICATIONS

• House, Office and Industrial wiring

• Telecom cable ducting

• Over and underground circuits

• Weather effect resistant

• Electric distribution circuit

MS/MILD

STEEL

Standard Product Range

0.5″ To 60″ (Pipes & Fittings)

Mild steel (MS) pipes are manufactured using low carbon (less than

0.25%) steel. Due to low carbon content the pipes do no harden and

are easy to use. As MS Pipes are made from mild steel they can easily

be welded and formed in various shapes and sizes for pipelining and

tubing purpose. Mild steel pipes category (Seamless, Welded). Seamless tube is extruded and drawn from a billet

While welded tube is produced from a strip that is roll formed and

welded to produce a

tube. Welded tube is considerably less expensive than seamless tube

and is readily available in long continuous lengths.

APPLICATIONS

• Drinking water supply

• Fire fighting

• HVAC (Heating, ventilation & air conditioning)

• Industrial & engineering applications

• In petrochemical, paper, dyes, paint, cement and industries

• Heavy Duty Projects

SS/STAINLESS

STEEL

Standard Product Range

0.5″ To 16″ (Pipes & Fittings)

Stainless steel is a versatile material comprised of a steel alloy and a

small percentage of chromium the addition of chromium adds to the

material’s corrosion resistance, a trait that earned

Stainless steel its name. Based on the end use of the pipe, stainless

steel piping is broken down into several categories. Most stainless

steel ordered around the world is Grade 304. It offers the standard

corrosion resistance, formability, strength, and easy maintenance for

which stainless is known.

While 316 come in second in terms of quantities sold, it offers vastly superior corrosion resistance to chlorides and acids. In easy words 304 is

not food grade material and cannot be used for food purpose.

APPLICATION

• Oil and Gas industry

• Nuclear Power

• LNG (Liquid natural Gas)

• Desalination , Mining & Minerals

• Food Industries( Dairy, cooking oil etc)

C.I/CAST

IRON

Standard Product Range

0.5″ To 16″ (Pipes & Fittings)

Cast iron pipe is pipe made predominantly from gray cast iron. It was

historically used as a pressure pipe for transmission of water, gas and

sewage, and as a water drainage pipe during the 17th, 18th, 19th and

20th centuries. Cast iron pipe was frequently used uncoated, although

later coatings and linings reduced corrosion and improved hydraulics.

APPLICATIONS

• Water Supply

• Drainage

• Industries

G.I/Galvanized

IRON

Standard Product Range

1/2″ To 12″ (Pipes & Fittings)

Galvanized Iron (GI) pipes are corrosion and rust resistant pipes that

are ideal for the transmission of potable water, natural gas, oil and

other fluids. They are also used in fencing, low cost shelters and general fabrication. GI pipes are certified as European Conformity Standards (CE) and are manufactured in accordance with the highest international standards (BS EN 10255:2004, ASTM A53, ASTM A795, EN39,

SLS829:2009)

APPLICATION

• Water supply

• Gas distribution

• Residential

• Industrial

• Major projects / Infrastructure

GATE/SLUICE

VALVES

Standard Product Range

B.S.S 3464 & 5163

25mm to 1200mm

Gate/Sluice Valves are usually manufactured from cast iron, cast

carbon steel, ductile iron, stainless, alloy and forged steel. Generally

used to completely shut off fluid flow or, in the fully open position, provide full flow in pipeline. Thus it can be used in fully open or fully closed

positions. A gate/sluice valve consists of (body, seat & disc, a spindle,

gland & a wheel for operating the valve.

APPLICATIONS

• Residential & Commercial

• Hot or Cold water

• Bio-gas, coal gas & natural gas

• For disposal of chemical effluent and waste

• External and internal drainage & water supply

• In petrochemical, paper, dyes, paint, cement and industries

CONNECTION CLAMPS / SADDLE

CLAMPS

Standard Product Range

0.5″ To 32″

Saddle clamps or connection clamps are made of different material

mild steel, stainless steel, high density polyethylene or polyvinyl chloride. They are basically used to get connection from one line, hanging

pipes or repairing pipes. Also known as u-Clamps

APPLICATIONS

• Water Supply

• Industry

• Residential or Commercial

• Gas distribution

CHECK / NON RETURN VALVE

(NRV)

Standard Product Range

B.S.S 3464 & 5163

25mm to 1200mm

Check/ Non Return Valves are usually made with good quality of plastic or metal. Various types of check valves are used in a wide variety of

applications. They are designed to permit water to flow in one direction and are a requirement on all submersible pump installations.

Their job is to prevent water in the column above the pump and in the

pressure tank from draining back into the well when the pump shuts

off.

APPLICATIONS

• Outlet side of the pump to protect the back flow

• Residential and Commercial use

• Heavy duty industries

• Government projects

• External and internal drainage & water supply

BUTTERFLY

VALVES

Standard Product Range

50mm to 1200mm

They can be made of a number of different materials such as stainless

steel, cast iron, aluminum, brass, bronze, or plastic, among others.

Usually the flange material is the same as the pipe itself. The area

where two pipes are joined together by a flange is known as a flange

joint. There are different type of flanges for different purpose (slip on

flange, socket weld, lap joint, stub end flange, thread flange, blind

flange etc).

APPLICATIONS

• Industry solution

• Infrastructure projects

• For disposal of chemical effluent

• External and internal pipelines

• Street poles

• Maintenance of water, gas, chemical pipelines

BALL

VALVES

Standard Product Range

20mm to 400mm

0.5″ to 14″

Ball valves are made using an assortment of materials, some of which

include brass, bronze, cast iron, copper ductile iron, metal alloys,

stainless and other steel types, and plastics (including CPVC and

PVC).A ball valve is a form of quarter-turn valve which uses a hollow,

perforated and pivoting ball to control flow through it. It is open when

the ball’s hole is in line with the flow and closed when it is pivoted

90-degrees by the valve handle. Type of ball valve (Socket, Thread,

Flange, Reducing).

APPLICATIONS

• Water work

• Waste water

• Power industries

• Oil & Gas production

• Refinery and petrochemicals

• Commercial and Residential

HIGH DENSITY P.E PIPEJOINTING

MACHINES

Standard Product Range

63mm to 1200mm

HDPE pipe is butt fused by applying heat to prepared pipe ends and

then pushing the pipe ends together with a pre-determined force to

make a permanent butt fusion joint. It is a very simple process utilizing

a properly sized butt fusion machine for the pipe size to be joined. P.E

Jointing machines are of two types (Hydraulic & Manual). Hydraulic

machine consist of machine stand in which pipe and fit, a heater for

jointing, hydraulic gauge and a cutter to shape up the edges. While

manual does not have hydraulic gauge.

APPLICATION

• Water and disposal P.E pipelines

• Industrial and commercial

• Bio-gas and oil fields

• Laying of external, internal P.E line